Components of Lateral Flow Tests Home>>Components of Lateral Flow Tests

Application

Contact Us

Components of Lateral Flow Tests

Creative diagnostics’ lateral flow assay (LFA) development service will take your assay development from initial idea, through to R&D and then transfer to trusted partners for bulk manufacturing.

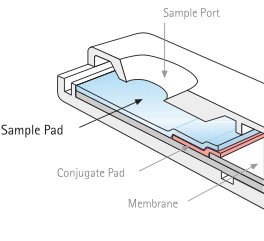

1.1 Sample Pad Selection and Specifications

The sample pad (Figure 1-1) can be used to promote the even and controlled distribution of the sample onto the conjugate pad. It may also control the rate at which liquid enters the conjugate pad, preventing flooding of the device. The presence of added protein (such as albumin) and detergents and surfactants (such as SDS or Tween-20 at a very low concentration) may promote resolubilization of the conjugate, reduce nonspecific binding of the conjugate, and possibly minimize adsorption of the analyte to the membrane.

Figure 1-1 Sample Pad

There are two types of materials that are commonly used as sample pads: cellulose fiber filters and woven meshes.

Woven meshes normally work very well to distribute the sample volume evenly over the conjugate pad. They also typically have good tensile strength and handle well, even when wet. Meshes have very low bed volumes, meaning that they retain very little sample volume, normally 1 – 2 µL/cm2. Meshes can also be expensive relative to other porous media and difficult to process through strip cutting machinery.

Cellulose filters have properties that are nearly the opposite of woven meshes. They are thick (> 250 µm), weak, and relatively inexpensive. Cellulosic filters are the most commonly used materials to make the sample pad because they can be loaded with a wide array of blocking agents, detector reagent release agents, pH and ionic strength modifiers, and viscosity enhancers. When using cellulose filters, care must be taken to ensure sufficient and consistent contact with the underlying conjugate pad material.

Specification of the sample pad depends greatly on its intended purpose in the test device. If the sample pad is being used primarily to modify the sample, the following attributes should be specified:

Thickness (Mean and Variability)

Mean thickness may be given as microns, millimeters, or thousandths of an inch (mils). The range of variability is also critical since this will affect the amount of bed volume and the consistency of compression in a housing. For strips placed in housings, the sample is typically applied to a port that exposes a small region of the sample pad. If the pad material is too thick, the fibers may be compressed so that absorption of liquid into the pad is greatly reduced or prevented. If the pad material is too thin, there may be little or no contact with the housing. This allows the sample to enter the housing unobstructed, flooding the interior, and significantly altering the flow dynamics of the test strip.

Basis Weight (Mean and Variability)

The basis weight is the mass of fibers per unit area. In the paper and non-woven industries, it is most often expressed as g/m 2. This value is of little relevance for lateral flow tests. Using the basis weight, the thickness of the material, and the density of the polymer, the bed volume and porosity can be calculated. Bed volume is directly proportional to thickness at constant porosity. Similarly, bed volume is directly proportional to porosity at constant thickness. Thus, variability in basis weight can be equated to variability in bed volume. Bed volume is actually the critical performance parameter, but it is rarely provided.

Tensile Strength

Tensile strength for sample pad materials is important for the same reason as for membranes. Some materials are as weak as unbacked membranes. Since they may be slit to widths of 1 cm or less, web handling can be very difficult in a continuous processing operation.

Extractables

Materials used to make sample pads contain binders to hold the fibers together. In addition, some of the fibers may break or not be interconnected with the pad’s macrostructure. Consequently, a considerable percentage of the pad’s components may be dislodged during various processing steps. When a test strip is run, this can lead to plugging and poor fluid transfer as the sample wets out the pad and moves downstream.

Dimensions (Length, Width)

The dimensions and tolerances should be completely defined.

Packaging, Labeling, and Certification

The considerations pertaining to membranes also apply to sample pad materials.

Particle Retention Rating

In some applications, the sample pad is used as a filter to remove particles from the sample before the liquid enters the conjugate pad. Thus, it is important to know the particle retention rating. Since these materials are depth filters, they do not exhibit 100% retention capability. Because of the way that papers and non-woven materials are manufactured, changing the particle retention rating often involves significant changes to the thickness and basis weight.

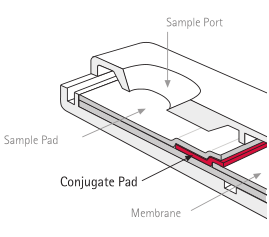

1.2 Conjugate Pad Selection and Specifications

The conjugate pad (Figure 1-2) can perform multiple tasks, the most important of which is uniform transfer of the detector reagent and test sample onto the membrane. When sample flows into the conjugate pad, the detector reagent solubilizes, lifts off the pad material, and moves with the sample front into the membrane. The ideal conjugate pad material has the following attributes:

1. Low non-specific binding. If the detector reagent or analyte binds to the conjugate pad, it will be unavailable to form the immunocomplex at the test line, thereby reducing signal intensity and sensitivity.

2. Consistent flow characteristics. Inconsistent flow properties can cause serious performance problems. If the material does not deposit the sample uniformly onto the membrane, the detector reagent may be channeled onto the membrane, appearing as streaks as the sample migrates along the membrane. Consequently, there will be uneven signal development at the test and control lines.

3. Consistent bed volume. When loaded into the conjugate pad by dipping, the amount of detector reagent in each test strip depends on the bed volume of the material. If the bed volume varies significantly, variable signal intensities may be observed even though all other components of the strip are constant.

4. Low extractables. In addition to chemical extractables, the material should be free of particles that can clog the membrane at the conjugate pad/membrane interface.

5. Good web handling characteristics and consistent compressibility. These attributes are important for incorporation into test strip manufacture and for consistent liquid transfer onto the membrane.

Figure 1-2 Conjugate Pad

The Role of the Conjugate Pad in Assay Sensitivity

An important function of the conjugate pad is to deliver the detector particles onto the membrane in a consistent volume of sample on every test strip. Ultimately, the sample volume required to release the detector particle into the sample stream determines how much analyte can be measured. Only the analyte contained in the volume of sample that migrates ahead of and with the detector particles can contribute to the signal. The volume of sample that enters the conjugate pad and membrane after the detector particles have been completely released does not contribute to signal, although it does serve to reduce assay background (Figure 1-2). Analyte that passes over the capture reagent line after all of the detector particles have migrated farther downstream may bind at the capture reagent line but will lack additional detector particles to complete the immunocomplex. The sample volume actually analyzed in the test strip equals the amount of sample required to solubilize the detector particles, not the total amount absorbed by the device.

The porous materials commonly used for conjugate pads are non-woven filters, which are manufactured by compressing fibers of cellulose, glass, or plastic (such as polyester, polypropylene, or polyethylene) into thin mats. They are specified by fiber size, thickness, basis weight, extractables, and air flow rate. In most cases, they cost considerably less than membranes. Materials commonly used to make conjugate pads include glass fiber filters, cellulose filters, and surface-treated (hydrophilic) polyester or polypropylene filters. The key properties for each are summarized in Table 1-1.

Table 1-1 Properties of conjugate pad materials

| Non-woven Material | Brief Description | Key Benefits | Key Liabilities |

| Glass fibers | 100-500 μm thick, may contain binders to hold fibers together | Good hold-up volumes, low nonspecific binding | Poor tensile properties, difficult to slit and web handle |

| Cellulose filters | 300-1000 μm thick, compact fibers of consistent density | Very low nonspecific binding, normally very uniform | High hold-up volumes (>50 μL/cm2), can be very weak when wet |

| Surface-modified polyester | 100-300 μm thick, hydrophilic polyster filters | Low nonspecific binding, excellent tensile strength and web handling | Low, and somewhat variable, hold-up volumes (<15 μL/cm2) |

The conjugate pad is as critical as the membrane in controlling the performance of lateral flow tests. As such, it is very important to define key material specifications:

Thickness (Mean and Variability)

Thickness may be given as microns, millimeters, or thousandths of an inch (mils). The range of variability is also critical since this will affect the bed volume and the consistency of compression in a housing.

Basis Weight (Mean and Variability)

The basis weight is the mass of fibers per unit area. In the paper and non-woven industries, it is most often expressed as g/m2. This value is of little relevance for lateral flow tests. Using the thickness of the material and the density of the polymer, the bed volume and porosity can be calculated. Bed volume is directly proportional to thickness at constant porosity. Similarly, bed volume is directly proportional to porosity at constant thickness. Thus, variability in basis weight can be equated to variability in bed volume. Bed volume is actually the critical performance parameter, but it is rarely provided.

Tensile Strength

Tensile strength for conjugate pad materials is important for the same reason as for membranes. Some materials are as weak as unbacked membranes. Since they may be slit to widths < 1 cm, web handling can be very difficult in a continuous processing operation.

Extractables

Materials used to make conjugate pads may contain binders to hold the fibers together. In addition, some of the fibers may break or not be interconnected with the pad’s macrostructure. Consequently, a considerable percentage of the pad’s components may be dislodged during various processing steps. When a test strip is run, this can lead to plugging and poor fluid transfer as the sample wets out the pad and moves downstream. Extraneous glass fibers can also present a health hazard in automated manufacturing systems.

Dimensions (Length, Width)

The dimensions and tolerances should be completely defined.

Packaging, Labeling, and Certification

The considerations pertaining to membranes also apply to conjugate pad materials.

Blood Filter Matrices

For analytes found in serum, a highly desirable performance attribute for a lateral flow test strip would be its ability to accommodate whole blood as the sample.

Porous media exist that are capable of separating cells from serum or plasma so that enough volume of sample is generated to run a lateral flow test. Efficient separation of blood cells from serum is extremely difficult. Blood contains 35% to 45% solids, mostly as red blood cells, meaning that a 200 μL aliquot of blood would be expected to yield at most 130 μL if the separation was 100% efficient.

In a lateral flow test, the filter material must be capable of functioning over the full range of blood variability, yielding enough serum to fill the bed volume of the entire test strip reproducibly and with the same flow kinetics. While several products have been commercialized as blood filters, they have not been widely accepted as components of lateral flow test strips. There are several patents describing materials and chemistries that can be used as blood separation filters. If the use of a blood separation filter is being considered, test strip developers may need to consider licensing one or more of these patents prior to commercialization of final product. EMD Millipore does not provide legal counsel, nor is it in the position of being able to assign any rights for any of the patents that have been issued. In the interest of providing useful information to users of lateral flow membranes, a list of pertinent patents can be found in the Appendix.

1.3 Membrane Selection and Specifications

The membrane is probably the single most important material used in a lateral flow test strip. Physical and chemical attributes of the membrane affect its capillary flow properties. The capillary flow properties in turn affect reagent deposition, assay sensitivity, assay specificity, and test line consistency. For lateral flow test strips, the membrane must irreversibly bind capture reagents at the test and control lines. Nitrocellulose membranes bind proteins electrostatically through interaction of the strong dipole of the nitrate esters with strong dipoles of the peptide bonds within the protein Nitrocellulose membranes have been manufactured for filtration purposes for many decades.

Figure 1-3 Membrane

Capillary Flow Time

Lateral flow membranes are evaluated on the basis of capillary flow time which is the time required for water to travel up and completely fill a 4-cm long strip of membrane. Which is the time required for water to travel up and completely fill a 4-cm long strip of membrane. Capillary flow time (s/4 cm) is inversely related to capillary flow rate, which is the distance traveled per unit time. Capillary flow rate is related to the size of the pores parallel to the plane of the membrane. As pore size increases, the flow rate of the membrane increases. When considering the test strip as a whole, the membrane is the material that normally determines the overall flow rate of the system and the time required to achieve a signal. Development of signals at the test and control lines is a non-equilibrium process, because the analyte and detector particles are being actively carried in the liquid stream and can interact with the capture reagents only for the brief time that they are sufficiently close at the molecular level. As soon as the last detector particles have passed the test line, no further signal development will take place. The effects of membrane flow rate and test line placement on sensitivity have been discussed extensively elsewhere.

Membrane Thickness

Membrane Thickness is important for several reasons. First, the volume of liquid required to saturate a given area of membrane is determined by the pore volume, which in turn is determined by the thickness of the membrane. For example, when a capture reagent buffer is dispensed onto the membrane, it is likely to spread farther on a thinner membrane. This can affect the width of the capture reagent line, which in turn defines the width of the signal line when the strip is run. Second, dispensing of the capture reagents onto the membrane can be affected by thickness variation. Third, membrane thickness is important when the strip is placed into a plastic housing. Standard nitrocellulose membranes can be as thin as 100 mm and as thick as 150mm. The range for a specific membrane is determined by the engineering design of the equipment used for its manufacture.

1.4 Absorbent Pad Selection and Specifications

Selecting an Absorbent Pad

Absorbent pads (Figure 1-4), when used, are placed at the distal end of the test strip. The primary function of the absorbent pad is to increase the total volume of sample that enters the test strip. This increased volume can be used to wash unbound detector particles away from the test and control lines, thereby lowering the background and enhancing assay sensitivity. Since the volume of sample that ultimately contributes to signal is controlled by the volume required to solubilize the detector particles, and not by the total volume of sample that enters the device, the addition of the absorbent pad may not have a dramatic impact on overall assay sensitivity. If the strip design does not include an absorbent pad, the volume of sample analyzed in the strip is determined solely by the bed volume of the membrane. There are two major considerations associated with the use of absorbent pads. First, a suitable material must be identified, specified, purchased, and integrated into the manufacturing process. Ultimately, this leads to a higher cost for the finished product. Second, an absorbent pad makes it difficult to incorporate an end-of-assay indicator in the test device. The flow of liquid through the absorbent pad is not necessarily laminar, and the pad may fill with liquid unpredictably.

Most absorbent pads are made from cellulose filters. The material should be selected on the basis of thickness, compressibility, manufacturability, and, most of all, uniformity of bed volume. Once an absorbent material has been chosen, optimizing the overall volume absorbed by the test strip is best managed by changing the dimensions (usually the length) of the absorbent pad.

Figure 1-4 Absorbent Pad

All of the specifications for the sample pad apply to the absorbent pad, with the exception of extractables.

1.5 Adhesive Card Selection and Specifications

For ease of handling during manufacturing, the porous materials comprising the test strip are usually mounted on an adhesive card. The adhesive card consists of three components: the plastic backing, the adhesive, and the release liner. Dimensions (length, width, thickness) and tolerances of the plastic backing must be specified. If the finished strip will be placed in a housing, the thickness of the plastic backing must be consistent so that the porous materials are not subjected to variable degrees of compression. The adhesive layer is in direct contact with the materials and chemistries critical to the functioning of the test strip. Key parameters to specify include thickness, extractables, volatile components, pressure sensitivity, temperature sensitivity, and shelf life. If the reagents are striped onto the membrane after it is mounted on the card, thickness variations for the plastic backing, adhesive layer, and membrane must be considered together. The striping mechanism should yield a uniform line appearance regardless of variations in aggregate thickness. For the release liner, the placement and tolerances on score marks must be specified. Contact of the membrane with the release liner should be avoided. To promote release from the adhesive, many liners are coated with silicone-based compounds. These compounds can transfer to the membrane, rendering the top surface hydrophobic.

This slight change in the surface chemistry can dramatically alter the consistency of liquid absorption during striping of the capture reagents.

1.6 Housing Selection and Specifications

Although not required, many lateral flow strips are placed into plastic housings. The housing prevents the user from applying the sample anywhere except the sample pad. In over-the-counter products for urine analysis, the housing also serves to protect the strip from inadvertent splash onto the membrane. External labeling on the housing can also be used to indicate the position of test and control lines and provide other information. Housings can be obtained as off-the-shelf cassettes or custom-designed to fit around the strip. Deciding between these options requires balancing unit cost, design costs, size compatibility with the strip, and requirements for external labeling. Ultimately, the dimensions and tolerances on the internal features need to be matched to the dimensions and tolerances of the materials that comprise the test strip. Internal pins and bars are used to hold the strip in place relative to the sample port and viewing window. They hold the materials in intimate contact with one another while the test strip is running. If these features are too large, the pads and membrane may be compressed to the point that sample flow is blocked. The plastic used for the housing must also be biocompatible.